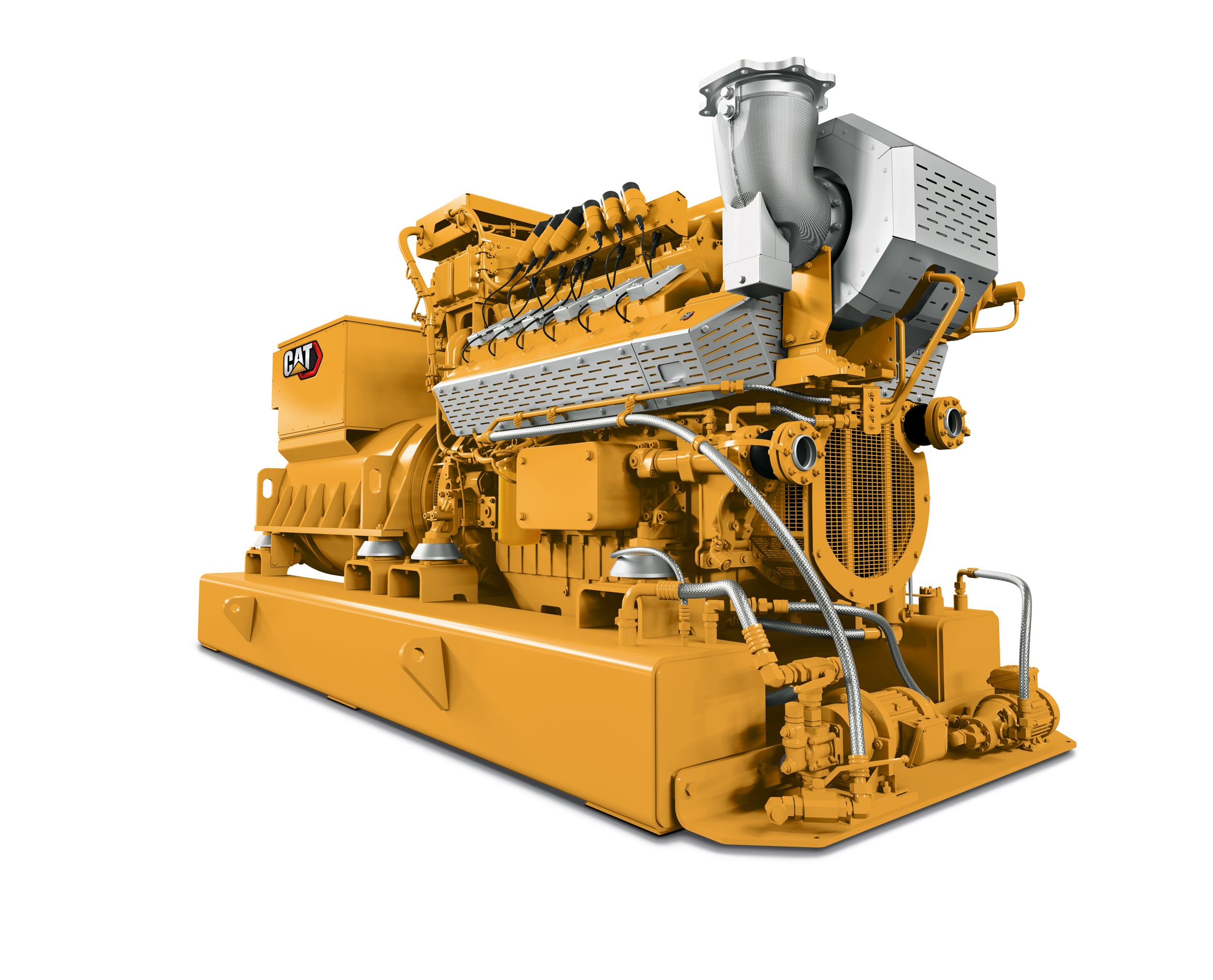

The Cat CG132B family of gas engines are perfectly tailored to the challenges of the power plant in an age of global value chains.<br>

<br>

Highly efficient with low operating and installation costs and lubricant consumption, the Cat CG132B gas generator set is available with outputs from 400kW to 800kW and comes with the Total Plant and Energy Management (TPEM) system.

|

|

|

|

|

|

|

|

Generator Set Specifications

- Continuous Rating

- 600 kW @1.0pf

- Fuel Type

- Natural Gas, Biogas, Hydrogen Blend (up to 25%)

- Maximum Electrical Efficiency

- 43.3% / 42.4%

- Maximum Standby Rating

- 600 kW

- Frequency

- 50 / 60 Hz

- RPM

- 1,500 / 1,800 rpm

Engine Specifications

- Engine Model

- CG132

- Displacement

- 1,604.9 in³

- Aspiration

- TA

- Bore

- 5.2 in

- Stroke

- 6.3 in

Generator Set Dimensions

- Length

- 151 in

- Width

- 70 in

- Height

- 85 in

- Dry Weight - Genset

- 15,432 lb

Standard Equipment:

-

- Air Inlet

-

- One-element single-stage air cleaner with enclosure and sevice indicator

- Turbocharger with a water-cooled bearing case for all cylinder

-

- Control Panels

-

- TPEM (Total Plant & Energy Management System)

-

- Cooling

-

- ANSI/DN customer flange connections for JW inlet and outlet

- flange connections for JW inlet and outlet

- Jacket water and SCAC thermostats

- Electrical jacket water and aftercooler coolant pump

-

- Exhaust

-

- Exhaust waste gate for the CG132B-16

- Closed crankcase ventilation system

- PEARL/Low resistence exhaust system

-

- Fuel System

-

- Independently controlled cylinder monitoring and ignition system

- Electronic fuel metering valve

- Pre-chamber spark plugs

-

- Generator

-

- Reactive droop

- grid code generator

- closed-coupled generator result in no torque transmission to the base frame

- Busbar connections

- Winding temperature detectors

- Anti-condensation space heater

- 3-phase sensing and KVAR/PF control

-

- Starting/charging

-

- 24V starting motors

- Battery disconnect switch

-

- General

-

- Crankshaft vibration damper and guard

Optional Equipment:

-

- Air Inlet

-

- Mounting stand

- Air cleaner with precleaner

-

- Cooling

-

- CHP skid

-

- Grid Code Compliance

-

- 50Hz: Germany, Belgium, Great Britain, Italy, Poland, and Netherlands

Specifications

Generator Set Specifications

- Continuous Rating

- 600 kW @1.0pf

- Fuel Type

- Natural Gas, Biogas, Hydrogen Blend (up to 25%)

- Maximum Electrical Efficiency

- 43.3% / 42.4%

- Maximum Standby Rating

- 600 kW

- Frequency

- 50 / 60 Hz

- RPM

- 1,500 / 1,800 rpm

Engine Specifications

- Engine Model

- CG132

- Displacement

- 1,604.9 in³

- Aspiration

- TA

- Bore

- 5.2 in

- Stroke

- 6.3 in

Generator Set Dimensions

- Length

- 151 in

- Width

- 70 in

- Height

- 85 in

- Dry Weight - Genset

- 15,432 lb

Standard/Optional Features

Standard Equipment:

-

- Air Inlet

-

- One-element single-stage air cleaner with enclosure and sevice indicator

- Turbocharger with a water-cooled bearing case for all cylinder

-

- Control Panels

-

- TPEM (Total Plant & Energy Management System)

-

- Cooling

-

- ANSI/DN customer flange connections for JW inlet and outlet

- flange connections for JW inlet and outlet

- Jacket water and SCAC thermostats

- Electrical jacket water and aftercooler coolant pump

-

- Exhaust

-

- Exhaust waste gate for the CG132B-16

- Closed crankcase ventilation system

- PEARL/Low resistence exhaust system

-

- Fuel System

-

- Independently controlled cylinder monitoring and ignition system

- Electronic fuel metering valve

- Pre-chamber spark plugs

-

- Generator

-

- Reactive droop

- grid code generator

- closed-coupled generator result in no torque transmission to the base frame

- Busbar connections

- Winding temperature detectors

- Anti-condensation space heater

- 3-phase sensing and KVAR/PF control

-

- Starting/charging

-

- 24V starting motors

- Battery disconnect switch

-

- General

-

- Crankshaft vibration damper and guard

Optional Equipment:

-

- Air Inlet

-

- Mounting stand

- Air cleaner with precleaner

-

- Cooling

-

- CHP skid

-

- Grid Code Compliance

-

- 50Hz: Germany, Belgium, Great Britain, Italy, Poland, and Netherlands