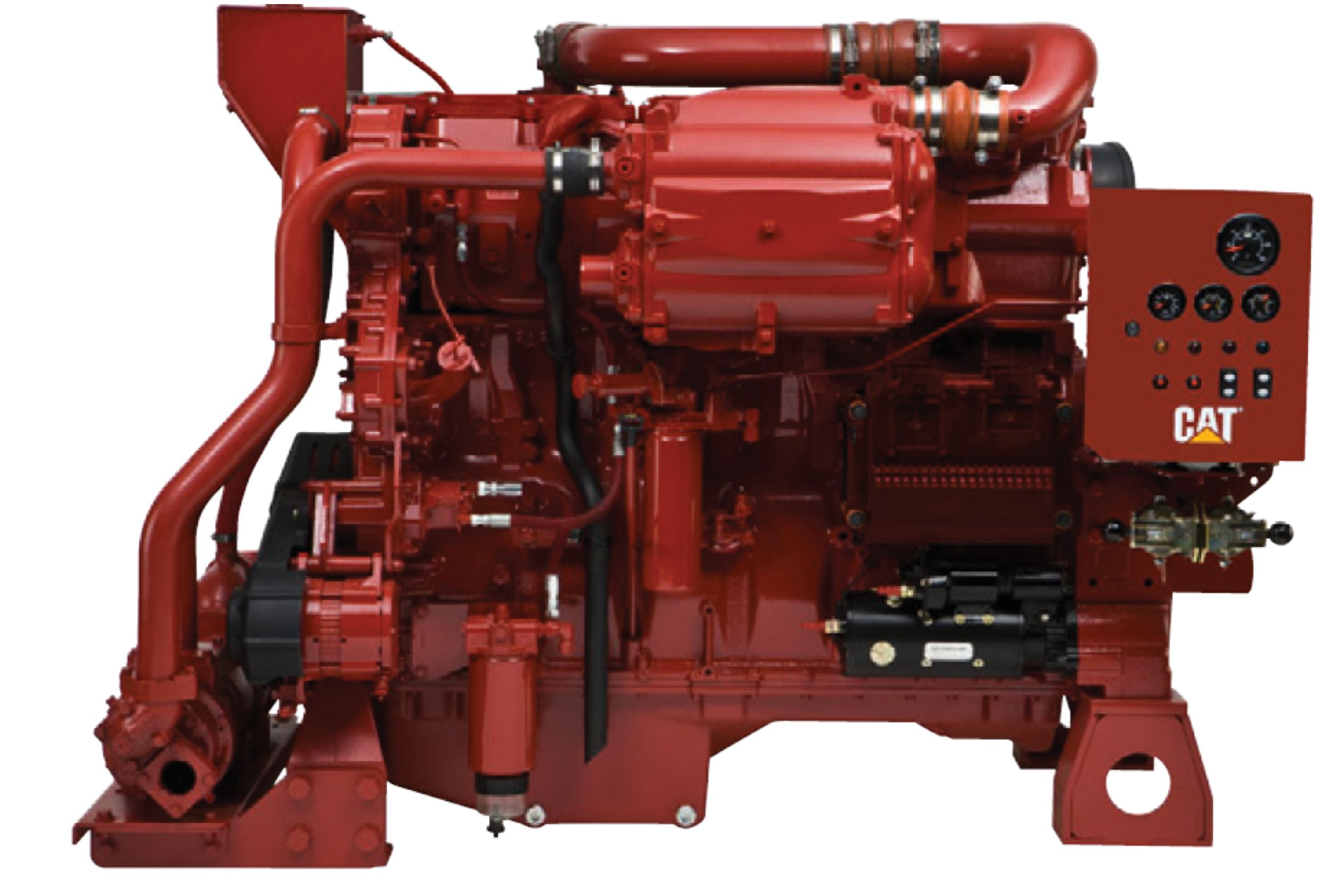

Cat C18 ACERT™ Fire Pump Engines. Ratings: 447-597 bkW (600-800 bhp)@ 1800-1900 rpm meet U.S. EPA Tier 3 or U.S. EPA Tier 2 emission standards for stationary emergency fire pump engines. Rating: 522 bkW (700 bhp) @ 1500 rpm is Non-certified. FM Approved. UL Listed.

|

|

|

|

|

|

|

|

Engine Specifications

- Minimum Rating

- 600BHP

- Maximum Rating

- 800BHP

- Emissions

- U.S. EPA Tier, Tier 2 or non-certified

- Rated Speed

- 1750r/min

- Bore

- 5.7in

- Stroke

- 7.2in

- Displacement

- 1106in³

- Aspiration

- Turbocharged-Aftercooled

- Engine Weight - Net Dry

- 3900lb

- Oil Change Interval

- 500h

- Rotation from Flywheel End

- Counterclockwise

- Flywheel and Flywheel Housing

- SAE No. 1

- Flywheel Teeth

- 113

Capacity for Liquids

- Lube Oil System - Refill

- 10gal (US)

- Cooling System - Engine

- 13.3gal (US)

Dimensions

- Length

- 74.4in

- Width

- 43in

- Height

- 54.3in

Standard Equipment:

-

- Air Inlet System

-

- Dual turbocharger: front and rear inlet 127.mm (5.0 in)

- Separate Circuit Aftercooled (SCAC)

-

- Charging System

-

- Charging alternator 24 volt, 50 amp

-

- Control System

-

- Dual Electronic Control Units (ECU), primary and secondary

- Electronic governing, PTO speed control

- Programmable ratings

- Cold start capability to -20° C (-4° F)

- Automatic altitude compensation

- Power compensation for fuel temperature

- Programmable low and high idle and total engine limit

- Electronic diagnostics and fault logging

- Engine monitoring system SAE J1939 broadcast and control

-

- Cooling System

-

- Thermostats and housing, vertical outlet

- Jacket water pump, centrifugal

- Heat exchanger installed

- Expansion tank

-

- Exhaust System

-

- Exhaust manifold, dry

- Dual turbo: exhaust elbow, dry 203 mm (8 in)

-

- Flywheels And Flywheel Housing

-

- SAE No. 1 flywheel

- SAE No. 1 flywheel housing

- Power take-off (PTO) flywheel stub shaft

-

- Fuel System

-

- Electronic unit injector

- Fuel filter, secondary (2 micron high performance)

- Fuel transfer pump

- Fuel priming pump

- Fuel sample valve, mounted on fuel filter base

- Primary fuel filter

- Water separator

-

- Instrumentation

-

- Instrument panel, LH

- Engine oil pressure gauge

- Voltmeter gauge

- Water temperature gauge

- Tachometer/engine hour meter

-

- Lube System

-

- Open crankcase ventilation system

- Oil cooler

- Lube oil filter

- Front sump oil pan

- Oil filler

- Oil dipstick

- Oil pump

-

- Mounting System

-

- Front and rear support

-

- Protection System

-

- Stop-Start System, automatic (compatible with NFPA 20 requirements, able to be energized from either of two battery sources and capable of manual starter actuation)

-

- Starting System

-

- 24 volt, LH electric starting motor

- Jacket water heater (3 kW, 120-240 volt)

-

- General

-

- Vibration damper

- Lifting eyes

- Automatic variable timing, electronic

- Electronic installation kit, 70 pin connector (connectors, pins, sockets)

Optional Equipment:

Specifications

Engine Specifications

- Minimum Rating

- 600BHP

- Maximum Rating

- 800BHP

- Emissions

- U.S. EPA Tier, Tier 2 or non-certified

- Rated Speed

- 1750r/min

- Bore

- 5.7in

- Stroke

- 7.2in

- Displacement

- 1106in³

- Aspiration

- Turbocharged-Aftercooled

- Engine Weight - Net Dry

- 3900lb

- Oil Change Interval

- 500h

- Rotation from Flywheel End

- Counterclockwise

- Flywheel and Flywheel Housing

- SAE No. 1

- Flywheel Teeth

- 113

Capacity for Liquids

- Lube Oil System - Refill

- 10gal (US)

- Cooling System - Engine

- 13.3gal (US)

Dimensions

- Length

- 74.4in

- Width

- 43in

- Height

- 54.3in

Standard/Optional Features

Standard Equipment:

-

- Air Inlet System

-

- Dual turbocharger: front and rear inlet 127.mm (5.0 in)

- Separate Circuit Aftercooled (SCAC)

-

- Charging System

-

- Charging alternator 24 volt, 50 amp

-

- Control System

-

- Dual Electronic Control Units (ECU), primary and secondary

- Electronic governing, PTO speed control

- Programmable ratings

- Cold start capability to -20° C (-4° F)

- Automatic altitude compensation

- Power compensation for fuel temperature

- Programmable low and high idle and total engine limit

- Electronic diagnostics and fault logging

- Engine monitoring system SAE J1939 broadcast and control

-

- Cooling System

-

- Thermostats and housing, vertical outlet

- Jacket water pump, centrifugal

- Heat exchanger installed

- Expansion tank

-

- Exhaust System

-

- Exhaust manifold, dry

- Dual turbo: exhaust elbow, dry 203 mm (8 in)

-

- Flywheels And Flywheel Housing

-

- SAE No. 1 flywheel

- SAE No. 1 flywheel housing

- Power take-off (PTO) flywheel stub shaft

-

- Fuel System

-

- Electronic unit injector

- Fuel filter, secondary (2 micron high performance)

- Fuel transfer pump

- Fuel priming pump

- Fuel sample valve, mounted on fuel filter base

- Primary fuel filter

- Water separator

-

- Instrumentation

-

- Instrument panel, LH

- Engine oil pressure gauge

- Voltmeter gauge

- Water temperature gauge

- Tachometer/engine hour meter

-

- Lube System

-

- Open crankcase ventilation system

- Oil cooler

- Lube oil filter

- Front sump oil pan

- Oil filler

- Oil dipstick

- Oil pump

-

- Mounting System

-

- Front and rear support

-

- Protection System

-

- Stop-Start System, automatic (compatible with NFPA 20 requirements, able to be energized from either of two battery sources and capable of manual starter actuation)

-

- Starting System

-

- 24 volt, LH electric starting motor

- Jacket water heater (3 kW, 120-240 volt)

-

- General

-

- Vibration damper

- Lifting eyes

- Automatic variable timing, electronic

- Electronic installation kit, 70 pin connector (connectors, pins, sockets)